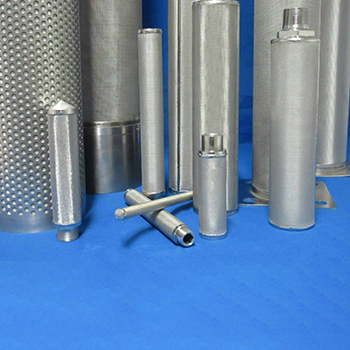

Product Overview

- Sintered multilayered mesh filter cartridges are manufactured from a various Wire-mesh Layers Pressed together and sintered at nearly 1000 Deg C Temperature to have rigid pore structure with Quantum of porosity under controlled environment.

- They are resistant to bacterial attack and compatible with a wide range of Chemicals.

- The multilayer mesh has a limited porosity of 30% and thickness of 1.7 mm and hasself-strength to get the cylindrical shape cartridges of required dimensions.

Features & Benefits

- End caps and connectors sealed by pulse tig welding hence sealed construction.

- Filter elements are electro-polished and dully cleaned in ultrasonic bath.

- Multi layers mesh structure is offering, absoluteFiltration efficiency

- Allowable Temperature :3000C

- Flux rate :10LPM per 10” long

Application

- Pharmaceuticalwater, Highly purified water, DM water, DI water.

- Process fluids, Solvents, Chemicals, Catalyst Recovery, Agitated Nutsche filter.

- Fluidization, Vacuum drying, Degassing.

Product Specifications

| No. | Specifications | Description |

|---|---|---|

| 1 | Filter media | SS 316L, Hastelloy |

| 2 | Core | Perforation or Spring |

| 3 | End cap | SS 316L or Hastelloy |

| 4 | Gasket/O-ring | As per requirements |

| 5 | Type of caps | DOUBLE OPEN END, CODEE VII, CODE II, BSP / NPT Thread |

| 6 | Filtration rating | For air & gas :0.2 , 0.5 , 1 , 3 , 5 , 10 , 20um For Liquids :1 , 3 , 5 , 10 , 20um |

| 7 | Outer diameter | Standard 64 mm & other diameters are available on request. Customized |

| 8 | Length | Standard 5” , 10” , 20” , 30” , 40” & Other lengths are available on request.. |