Product Overview

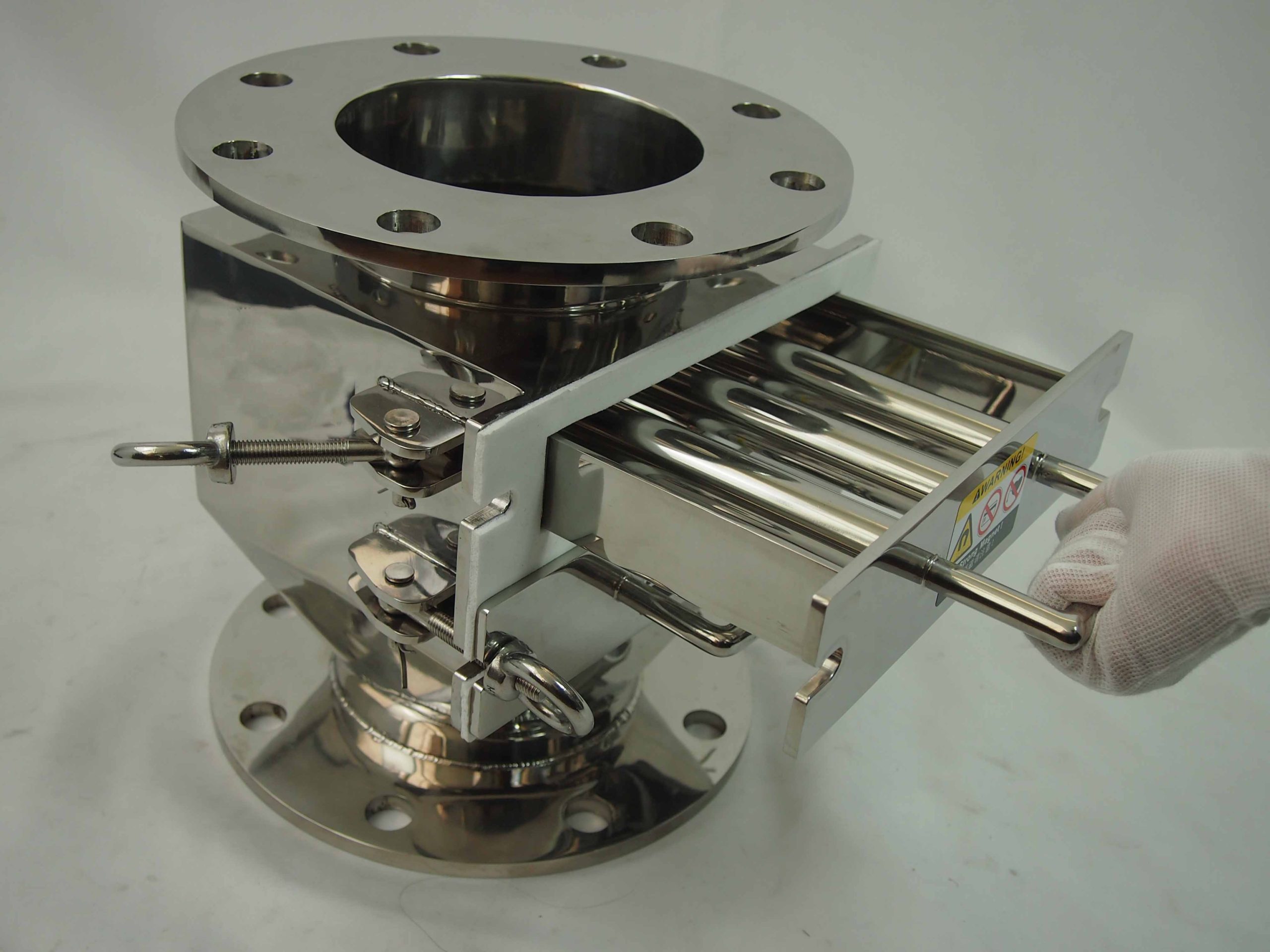

- Magnetic filters are installed along the passage of fluid. The flowing liquid is passed through magnetic field of high intensity filter magnets where fine ferrous particles get arrested in a magnetic trap.

- These arrested fine iron particles can be removed manually after removing the top lid of the filter. Drain plug is provided at the bottom of Filter unit for periodical cleaning of the filter system.

- The Magnet rods are enclosed in stainless steel housing making it suitable for use in Chemical, Paper & Ceramic Industry. TheMagnetic Filter is easily removable from the stainless-steel enclosure by loosening a few quick releasefasteners.

Features & Benefits

- High-intensity magnets remove virtually all particles and clean fluid continues uninterrupted.

- Rust particles are removed from the magnet and can be recycled with minimal fluid loss.

- Magnetic design means that the filter will not block, so there is no blinding or pressure build up.

- Cleaner, Longer Lasting Fluids& Minimum Fluid Loss.

- Reduced Expenditure on Consumable Filters.

- Reduced Waste Disposal with Continuous 24/7 operation.

- Fluid protection&rapid return on Investment.

Application

- Compressed Air, Gases.

- Water filter, Process fluids, Chemical, Fuel, Oil, Solvents etc.

- Automotive Manufacturing Industries

- Magnetic Separation in food, Chemical, Pharmaceuticals, Sugar industries,Paper,Textile.

Product Specifications

| No. | Specifications | Description |

|---|---|---|

| 1 | Filter media | SS304, SS 316L, Hastelloy |

| 2 | Gauss Power | 5500,6500,9000, 10000 &up to 13000 Gauss |

| 3 | Outer diameter | 25 , 32 , 40 , 50 mm OD |

| 4 | Length | 10” , 20” , 30” , 40” & Customized |